Integrating an imaging solution into a new or existing system may seem like an overwhelming and costly process at first. Consumer-grade, off-the-shelf point and shoot cameras can sometimes do the job, providing an inexpensive short-term solution, but they often lack in features, capabilities, support, warranty eligibility and fail to meet the exact needs of a customer’s application. Turning to an OEM and custom camera manufacturer to provide an imaging solution for a customer’s unique requirements may sound like it would be a more expensive option, but this isn’t always the case. Since the customer is provided with a longer-term solution that matches their application needs exactly, the integration of a custom imaging solution often ends up being more cost effective and a more reliable solution in the long run.

Lumenera has worked with many customers over the years to help integrate cameras into their products or systems through our OEM and custom design services. An OEM camera project can be as simple as providing a stock camera without a Lumenera logo on the enclosure, matching pantone colors to customer’s current branding/color schemes, and custom labelling with specific part numbers, or as complex as custom designed hardware and software. Common hardware modifications include changes to the camera’s enclosure, the removal of the camera’s protective cover glass and/or the image sensor’s protective cover glass from the optical path. Simple modifications to the camera’s software are also possible such as rebranding onscreen interfaces.

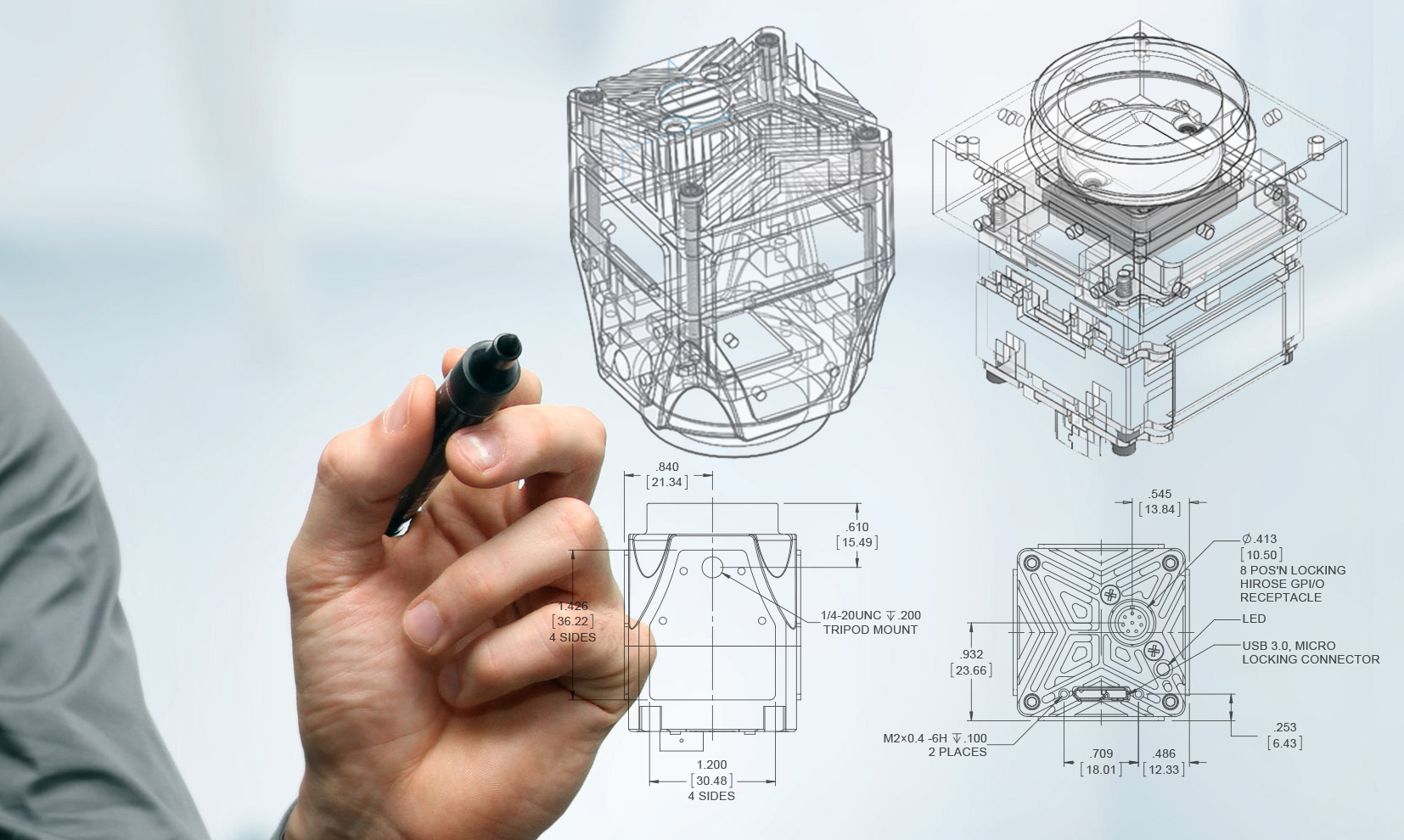

A custom imaging project often starts with an existing Lumenera camera which can be modified to suit the customer’s exact application. The camera’s form factor can be completely re-designed in order to be integrated into a final product or system. New software features can also be created to perform specific tasks and the API or SDK can be modified to integrate the camera into a larger system.

Lumenera also works with customers to create entirely new custom camera designs, including fully enclosed or board-level solutions. Lumenera’s approach to such custom projects is to be as flexible as possible, working with customers to provide fast turn-around on fully custom designs.

Since camera assembly is performed at Lumenera headquarters in North America, quality control measures can easily be adapted to meet customer requirements, such as meeting EMI requirements for FDA approvals. Testing software can be modified to perform application-specific tests, while new tests can be developed using customer equipment such as specialized computing platforms or complete end-user systems.

If you’re looking for an imaging solution and haven’t yet found a camera that meets your requirements, keep in mind that any standard Lumenera product can be adapted to meet your exact application needs. From small, low-cost tweaks and modifications, to complete made-to-spec solutions, consider partnering with Lumenera to create a custom imaging solution that's right for you.