Growing cells in culture dishes or flasks has been in practice for many decades. Traditionally samples from these flasks are collected on a regular basis to determine, among other things, their density and viability. Along with visual inspection of the flasks under a microscope, it was common practice to determine both density and viability using an instrument called a haemocytometer. This manual method was accurate but it had its disadvantages. Continually cleaning, counting and manually logging data was a tedious process. Furthermore, there were biohazard considerations to take into account when carrying out this manual process.

Consequently, there has been a proliferation of automated cell counters introduced to the market in the past 10 years. Advances in digital imaging cameras and the development of unique detection and identification algorithms have led to the growth in new cell counter instrumentation that allows for a safer, faster, and easier process. Automating the cell counting process has led to greater throughput, the minimization of biohazard concerns, overall time savings, and more accurate data capture and documentation of results.

Lumenera has supplied a variety of imaging technologies to automated cell counter manufacturers. Camera resolution, frame rate and sensitivity are matched to the various cell-counting tasks required for the application. For example, general cell counting and viability are used in conjunction with Trypan blue stain. The stain does not pass through the intact membrane of healthy cells but stains the damaged or dead cells. In this application, the manufacturers chose to make use of our 3 or 5 megapixel CMOS sensor technology. Streaming data over an USB 2.0 interface, the manufacturer’s software is able to distinguish both total cell numbers and differentiate between healthy and dead cells. Our CMOS cameras provide ample resolution and superior color reproduction at very competitive price points. This is important given that these are becoming basic tools for every tissue culture lab. Furthermore, once a Lumenera customer has made use of our SDK and API library to integrate the first camera, subsequent camera integration for higher end applications is a short, time-saving step.

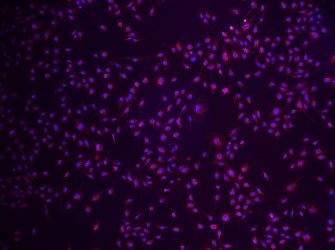

Other manufacturers that Lumenera has worked with have more demanding applications requiring enhanced cellular resolution. Low-to-high cell density as well as a variety of cell types found in primary cell cultures increases the demand on the imaging requirements. In these cases, manufacturers have identified a variety of Lumenera CCD based USB 2.0 and USB 3.0 cameras to meet the requirements. The cameras provide both higher dynamic range and resolution to meet the increasing demands of these brightfield applications. In recent years, cell counter manufacturers have introduced fluorescent imaging techniques as part of their overall offering. Protein expression and cytotoxicity are among the many applications made available through fluorescent analysis and quantification. Lumenera’s single-stage cooled cameras and most recently the introduction of the INFINITY3S-1UR USB 3.0 camera equipped with the new Sony ICX825 sensor are providing the increased sensitivity that manufacturers demand.